CONSULTING

TESTING

DEVELOPMENT

RESEARCH

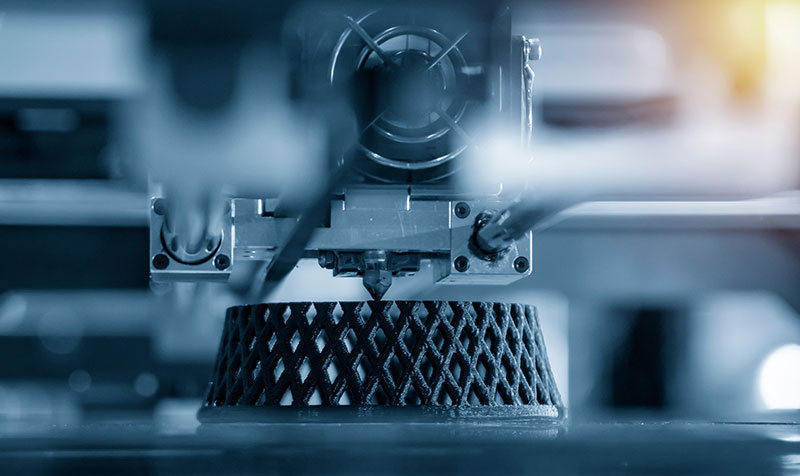

Additive Manufacturing with AAC

Additive Manufacturing Technologies

Additive Manufacturing Technologies offer new capabilities on the design for complex parts. However, based on our extensive expertise at AAC there are still several drawbacks on the materials & processing side to overcome, e.g.:

- Availability and price of raw materials for AMT relevant for space applications (light weight, high stiffness, high strength, low cte, demisable, etc.);

- Materials properties depend strongly on the Additive Manufacturing Technology as well as on the processing & post-processing parameter. Thus, materials & components are usually not similar to their conventional produced counterparts (e.g. microstructure, surface roughness, mechanical properties like strain at failure, etc.);

- Quality Assurance for the reproducibility of Additive Manufactured parts, e.g. in-situ monitoring and NDI are needed.

AAC as ESA certified Testhouse is specialized in materials & components testing especially in space relevant environments (4K – 2,300K). Since 2010, AAC is working together with 3D printing partner companies on the improvement of their 3D Printing Systems to develop new materials and components for conventional and especially space industry. These projects are mainly b2b contracted or funded by the Austrian FFG or European Space Agency. AAC is offering for the development projects of their partner its expertise in the characterization of the materials properties and components, e.g. microstructural investigations by SEM, quasistatic and dynamic mechanical properties (strength, strain, fatigue), stress corrosion cracking, non-destructive testing, etc..

As the use of additive manufacturing (AM), or 3D printing, continues to grow across various industries, our team of dedicated experts leads the way in providing the most extensive range of additive manufacturing testing services available.

We are a trusted testing partner for customers in the aerospace, medical, transport, and energy sectors, playing a crucial role in developing rigorous international testing standards for additive manufacturing. Our early qualification in these highly regulated industries, known for their stringent validation processes, underscores our commitment to safety and quality.

Ensuring Safety and Suitability in Critical Applications

Our mission is to ensure that materials and products created through additive manufacturing are safe and suitable for critical applications. Our extensive suite of testing services includes:

- Powder Characterisation

- Chemical Analysis

- Defect Analysis

- Fatigue Testing

- Tensile Strength Testing

- Impact Testing

- Hardness Testing

- Creep and Creep Rupture Testing

- Fracture Toughness Testing

- Compression Testing

Leading the Way in Additive Manufacturing Technology

We address the unique challenges posed by additive manufacturing, such as defining inspection requirements, creating reliable quality assurance programs, determining material properties susceptible to AM processes, and identifying critical defects with unparalleled accuracy and detail.

By collaborating with industry leaders, academic institutions, and public organizations, we stay at the forefront of advancements in additive manufacturing and inspection methods. This collaboration ensures the continued success and integration of these innovative manufacturing technologies.

Explore our comprehensive testing services to see how we can support your additive manufacturing needs, ensuring the highest standards of safety, quality, and performance.