CONSULTING

TESTING

DEVELOPMENT

RESEARCH

Development of Test Methods and Facilities

Development of new test methods and facilities

AAC’s expertise in mechanical and electrical engineering, together with software engineering can contribute to space testing also with customer adopted test setups (MGSE and EGSE). This starts with simple adaptors to host new gear boxes in our test devices, but may comprise also complete new setups to test components under thermal vacuum for life. Even providing torque loads or software to control motion profiles and record data.

Besides that, AAC is observing demands by industry in testing of materials and components (structure, mechanisms), whereby a certain focus herein is put on space. In case of lack of very specialist test methods, AAC is developing new test facilities which are then used to offer test services to industry and R&D-entities, both within funded projects (EU, FFG) and ESA-activities but also in direct orders to industry.

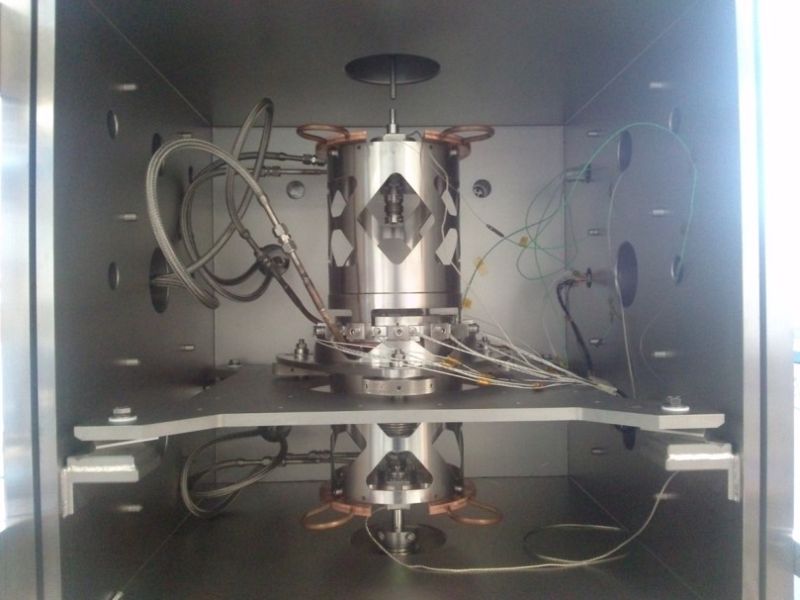

Examples for such test service can be seen on our WEB-pages: The Fretting test devices were developed to validate the risk of certain material combination towards cold welding (stiction, adhesion) during launch. Advanced Outgassing offers in-situ mass loss in thermal vacuum combined with in-situ monitoring of outgassing species by ConMon. The seldom effect for moisture expansion /contraction in vacuum can be measured with the “CME” test device. Electrical Slip-rings can be tested from air to vacuum conditions. A cryo tribometer and a cryo mechanics setup were developed that offer cost efficient testing even down to cryogenic temperatures (Liquid Helium LHe).