Fracture mechanics testing of composite materials at cryogenic temperatures is essential for assessing their performance in extreme environments, such as those encountered in aerospace, space exploration, and cryogenic fuel systems. These applications require materials that can withstand significant mechanical stresses while operating at temperatures far below room temperature, often approaching absolute zero. At cryogenic temperatures, composite materials exhibit different mechanical properties compared to their behaviour at ambient temperatures, making it crucial to understand how cracks initiate and propagate in these conditions.

Fracture mechanics testing at cryogenic temperatures is vital for improving the design and safety of composite materials used in cryogenic environments. The data collected from these tests enable engineers to better understand the material’s behaviour at extremely low temperatures, thus ensuring that composite structures perform reliably and safely in aerospace and other high-performance applications.

Challenges at Cryogenic Temperatures

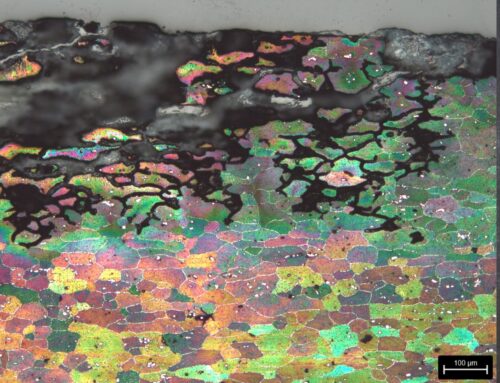

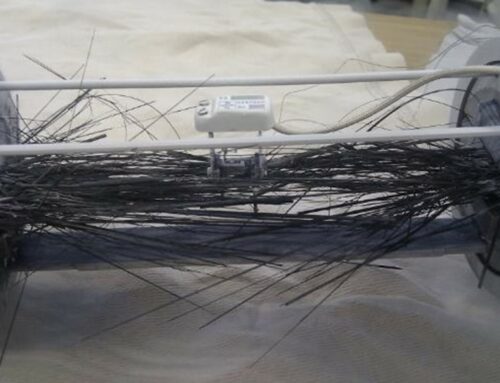

At cryogenic temperatures, the fracture toughness of composite materials typically decreases because the matrix becomes more brittle, which leads to earlier crack initiation and rapid crack propagation. As composites are made up of a polymer matrix reinforced by fibres, the matrix is particularly sensitive to temperature changes. In cryogenic environments, the matrix often become more rigid, reducing its ability to dissipate energy and slowing crack growth, but also making it more prone to catastrophic fracture under applied stresses.

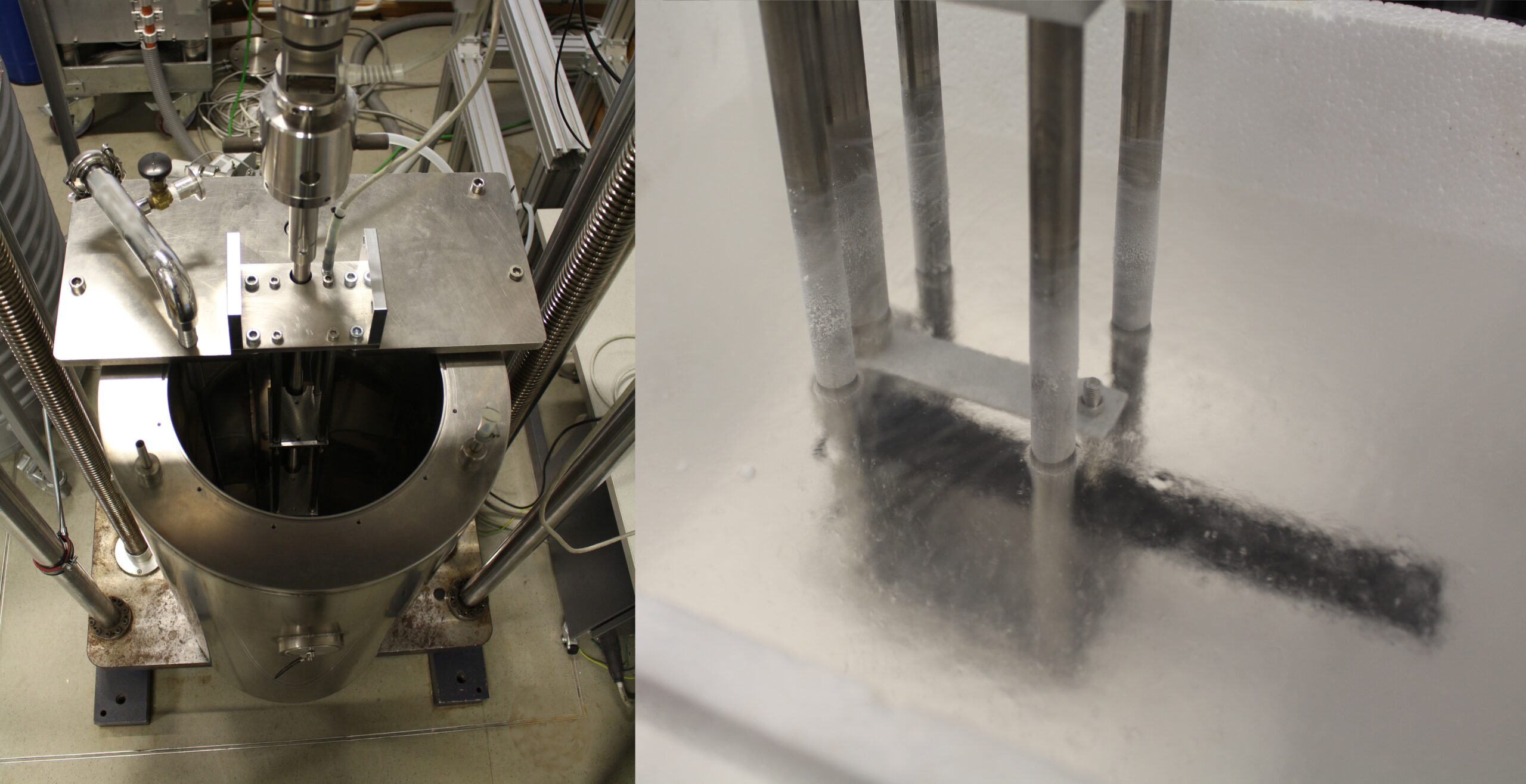

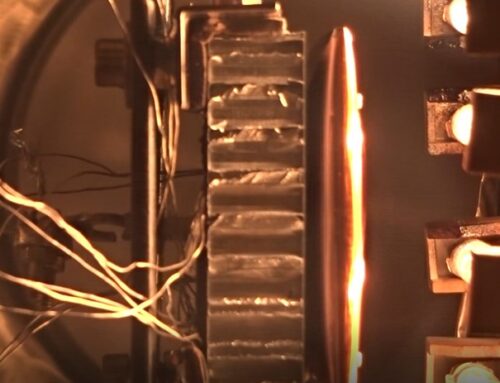

To accurately measure fracture toughness at cryogenic temperatures, the testing apparatus needs to be modified to operate in low-temperature environments. A cryogenic chamber is used to lower the temperature of the specimens to the required test conditions, often ranging from liquid nitrogen temperatures (-196°C) to even lower temperatures found in space or cryogenic fluid systems. During testing, it’s important to monitor not only the fracture toughness values but also the rate of crack propagation to ensure that the composite’s behaviour under stress is well understood.

In practice, the determination of in-situ crack length by optical methods in cryogenic environment is very complicated and not applicable.

Conclusion

AAC’s proven knowledge and extensive experience using the area method for determination of fracture toughness at cryogenic temperatures down to 4.2K (LHe) deliver accurate fracture toughness measurements that are crucial for predicting the long-term durability of composite components in aerospace and cryogenic applications, where even small flaws or cracks can lead to catastrophic failure. The fracture toughness values obtained from these tests are used in design guidelines to ensure that composite structures will perform safely and reliably at low temperatures. Engineers use this data to refine their models and ensure that composite materials can meet the demanding performance criteria for applications in space vehicles, cryogenic fuel tanks, and other high-stress environments.

Interested in more information or mechanical cryogenic testing services? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Cryogenic mechanical testing