The release of volatile organic compounds (VOCs) from synthetic materials, is a well-known concern on Earth, particularly for its impact on human health. VOCs are emitted from a range of products, including plastics, paints, and adhesives, especially when these items are new or exposed to certain environmental factors like light, temperature, or radiation. While we often focus on the human health risks, such as potential links to cancer, the release of material also presents a significant challenge in environments where sensitive equipment is involved, particularly in space.

Outgassing vs. Offgassing: Understanding the Difference

Before diving into the specific risks associated with material release, it’s important to clarify the difference between OUTgassing and OFFgassing, as these terms are sometimes used interchangeably.

- Outgassing refers to the release of gases trapped within a material when exposed to high-temperature environment under vacuum. This term is commonly used in the context of space applications or other high-reliability environments where the absence of atmospheric pressure in combination with high temperatures cause materials to release gases that can interfere with sensitive equipment such as optics, electronics and other delicate instruments.

- Offgassing, on the other hand, describes the release of organic compounds and other chemicals from materials at room temperature under normal atmospheric conditions. This process is more commonly associated with indoor air quality concerns, such as the emission of chemicals from new furniture, carpets, or building materials, which can affect human health over time but can also have impact on sensitive technical components.

While both terms describe the release of gases from materials, outgassing is particularly relevant in specialized environments like space, where it poses a direct threat to the performance and reliability of electronic systems and other sensitive hardware. Offgassing is crucial to consider in environments such as data centres or medical facilities, where air quality can impact both human health and equipment performance.

Offgassing and its impact on Electronics

In tightly controlled indoor environments with a high concentration of electronics, such as data centres, the accumulation of VOCs can be problematic: These compounds can cause corrosion or deposit contaminants on sensitive components, diminishing their performance and reliability. This issue is particularly concerning for scientific instruments and medical devices, where VOC buildup on mirrors, lenses, and sensors can severely impair their functionality. Additionally, electric connectors may suffer from degraded signal quality due to the accumulation of VOCs on contact surfaces. To address these risks, engineers may use sealed, IP-rated connectors and implement air filtration and ventilation systems to reduce VOC exposure.

The Space Environment: A Unique Challenge for Outgassing

In the vacuum of space, the outgassing of materials becomes a significant issue. Unlike on earth, space presents an environment where materials, especially plastics, release gases that can then collect on critical components of satellites and spacecrafts. This can lead to severe complications, such as obstructing the view of optical instruments, which are essential for data collection during missions. Furthermore, the properties of a material which suffers from outgassing may change due to the release of specific components (e.g., change in mechanical properties due to loss of softening agents)

Key Standards for Outgassing in Space Applications

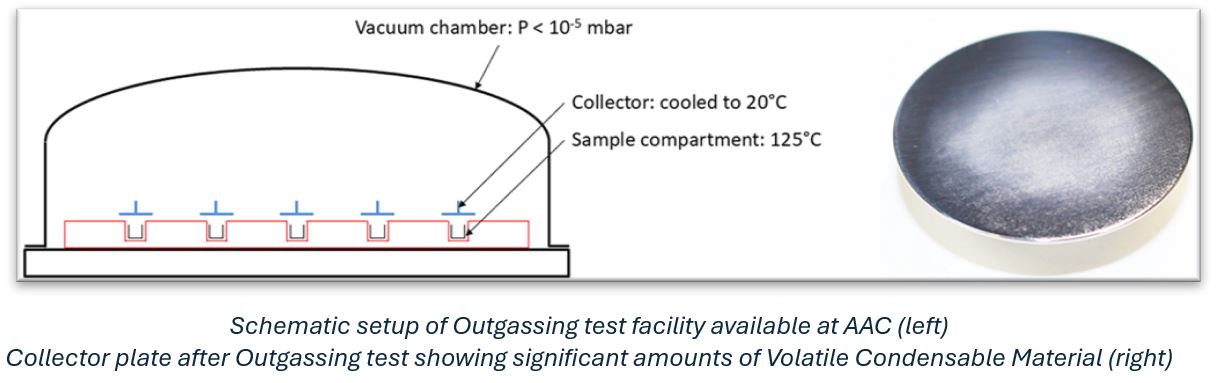

To mitigate the risks posed by outgassing in space, various organizations, including NASA, the European Space Agency (ESA), and the American Society for Testing and Materials (ASTM), have established guidelines and standards. The three key standards in this area include:

- ASTM E595: “Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment.” This standard describes the test method required to quantify the outgassing process and defines the acceptance limits.

- ECSS-Q-TM-70-52A: “Kinetic Outgassing of Materials for Space.” This standard provides guidelines for measuring the rate, at which materials outgas under space conditions. This can help engineers to select materials that maintain stable over time. However, no specific limits are defined.

- ECSS-Q-ST-70-02C: “Thermal Vacuum Outgassing Test for the Screening of Space Materials.” This ESA-standard focuses on testing materials under thermal vacuum conditions to screen for outgassing properties, ensuring that only suitable materials are used in space applications. The following acceptance limits for outgassing are defined:

- Total mass loss (TML) < 1,00%

- Regained mass loss (RML) < 1,00%

- Collected Volatile Condensable Material (CVCM) < 0,10%

Compliance with these standards is crucial for ensuring that components used in space applications perform reliably, minimizing the risk of outgassing-related issues that could compromise the mission.

Key Standards for Offgassing in Controlled Environments

In environments where offgassing is a concern, adhering to specific standards is essential to maintain air quality and protect both human health and sensitive equipment. The most relevant standards include:

- ECSS Q-ST-70-29: This standard outlines the requirements for offgassing in environments where maintaining low levels of airborne contaminants is critical. It provides guidelines for selecting and testing materials to ensure that they do not emit harmful VOCs that could compromise air quality or the performance of sensitive instruments.

- VDI 2083-17: This guideline, part of a broader series on cleanroom technology, specifically addresses the control of offgassing in cleanrooms and other controlled environments. It provides detailed recommendations for material selection, testing, and monitoring to minimize the release of contaminants.

Adhering to these standards helps ensure that materials used in critical applications are safe and effective, minimizing the risks associated with offgassing.

Guidelines for Space Applications

Designing components for space missions requires careful material selection and rigorous testing. Engineers are required to use advanced simulation tools to ensure that chosen materials meet both outgassing and performance criteria. Even small changes in material composition or in the production process can affect the functionality of sensitive applications, making thorough testing and validation essential.

Specialized Techniques to Minimize Outgassing

To reduce the potential for outgassing, manufacturers often employ specialized processes. For example, components may undergo a so-called “bakeout procedure” in dedicated ovens, which exposes them to temperatures above the actual operation temperature to force outgassing before the components are used in mission-critical applications. This process helps to reach the outgassing limits, which is vital for the usage of materials in the extreme conditions of space.

Other manufacturers utilize vacuum ovens to extract VOCs from components, ensuring that they meet the necessary standards before deployment. These processes are part of a broader strategy that includes careful testing, curing, and packaging to minimize the risk of outgassing. For instance, components are typically transported in specialized packaging that includes humidity indicators, allowing to monitor and mitigate of any environmental changes during transport.

In the production of space-grade materials and components, a proper material selection is the key to control the outgassing behaviour. Depending on the final application, specific materials such as polyimides or PTFE are chosen to provide low outgassing properties. On the other hand, alternative manufacturing processes, such as potting, are carefully managed to ensure that the final products are suitable for use in space.

Given the rapid advancements in space technology, continuous monitoring and validation of new materials is necessary to maintain compliance with the latest standards and ensure that components meet the specific demands of each mission.

Conclusion

Outgassing represents a significant challenge to the reliability of sensitive electronics, particularly in space and other high-demanding environments. However, by carefully selecting materials, adhering to standards such as ASTM E595 and ECSS-Q-ST-70-02C and utilizing specialized processes, manufacturers can produce components capable to withstand these harsh conditions. These efforts are crucial to ensure the long-term performance and reliability of critical components in the most demanding environments.

Offgassing poses a risk for human health as well as for the functionality of sensitive equipment operated in tightly controlled indoor environments. Adhering to standards such as ECSS Q-ST-70-29 and VDI 2083-17 can help to define materials and processes to mitigate offgassing issues.

Interested in more information? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Space Engineering & Technology