CONSULTORÍA

PRUEBAS

DESARROLLO

INVESTIGACIÓN

Ensayos de (micro)dureza

Materiales avanzados, métodos orientados a la solución, exámenes cualitativos y cuantitativos

Hardness testing is a crucial process in the metal industry to measure a material’s resistance to deformation. It allows for the determination of properties such as strength, toughness, and abrasion resistance, which are critical for selecting and processing materials. Various testing methods enable the precise measurement of a material’s hardness, which forms the foundation for further treatment and application of the material.

Methods of hardness testing

To assess the hardness of a sample, a penetrator is pressed onto the material surface with a set test force. The resulting permanent impression left by the penetrator is measured to calculate the penetration depth and subsequently the hardness of the material. Various methods exist, each suited for different material types and requirements:

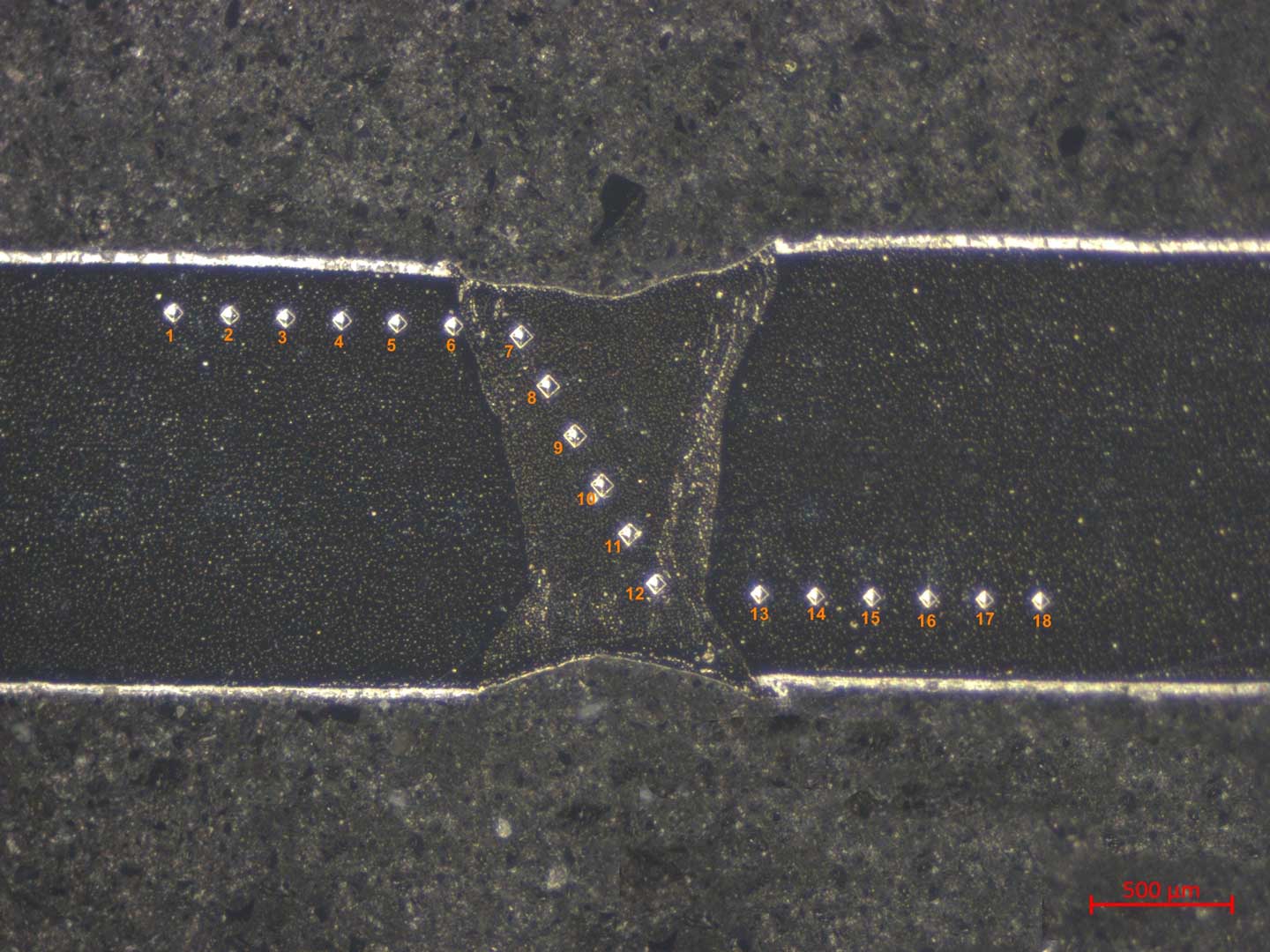

- Vickers Hardness Testing: The most frequently used method of hardness testing is Vickers method: it is very versatile and suitable for both large and small material samples. It uses a diamond pyramid and is often applied to testing welds and thin components.

- Brinell Hardness Testing: This method is ideal for materials with coarse grain structures. It uses a tungsten carbide ball and is well-suited for testing large material samples.

- Rockwell Hardness Testing: This method is particularly efficient and suitable for a wide range of materials. It allows quick measurements and provides instantly readable results. It is often used for hardened steel and cast iron. As penetrator, a steel ball is used.

- Knoop Hardness Testing: The Knoop method is particularly useful for brittle materials or thin coatings, as it works with low pressure, preventing the formation of cracks. A rhombohedral diamond indenter is used.

These testing procedures are based on international standards, ensuring comparable results:

- ISO 4545: Metallic materials — Knoop hardness test

- ISO 6506: Metallic materials — Brinell Hardness Test

- ISO 6507: Metallic materials — Vickers Hardness Test

- ISO 6508: Metallic materials — Rockwell Hardness Test

- DIN 51917: Testing of carbonaceous materials — Rockwell Hardness Test

- ASTM C886: Standard Test Method for Hardness Testing of Carbon and Graphite Materials

- ASTM E10: Standard Test Method for Brinell Hardness of Metallic Materials

- ASTM E18: Standard Test Method for Rockwell Hardness of Metallic Materials

- ASTM E92: Vickers hardness and Knoop hardness in the low force range

- ASTM E384: Standard Test Method for Microindentation Hardness of Materials acc. to Vickers and Knoop

The choice of the appropriate hardness testing method and applied load depends on several factors, including the material type, its hardness, and the precision requirements. For materials with heterogeneous structures, a larger testing range may be required, while micro-hardness tests are preferred for very thin components or coatings.

Depending on the method, specific surface preparation procedures may be required to optimize the material surface for measurement. For macro hardness tests, a fine grinding is usually sufficient, while microhardness tests may require polishing or electropolishing to achieve a clean and clearly visible measurement edge and a proper evaluation of the resulting hardness.

Hardness measurement at AAC

Modern state-of-the-art equipment available at AAC enables the (fully automated) investigation of hardness with loads in the range of 0,25 g – 62,5 kg. Furthermore, harness mappings (e.g., line-scans, matrix-scans) can be performed to assess the lateral distribution of mechanical properties. The key features of the hardness tester available at AAC include:

- Wide test force range (0.25 g – 62.5 kg)

- Dynamic test turret with 8-position tool changer

- White LED light with motorized aperture shuttering

- Fully automated, unmanned test and analysis cycles

- XYZ axis control with direct optical path measuring system

- Sample image camera with automatic image acquisition (resolution of 0,5 µm)

Applications of Hardness testing

Hardness testing is widely used in many industrial sectors, particularly in metalworking, quality assurance, and material inspection. Key applications include:

- Quality Assurance: Hardness testing ensures that materials possess the required mechanical properties to perform their intended function. It is particularly essential when controlling welds and evaluating heat treatments.

- Material Identification: Hardness tests can be used to identify and differentiate various materials.

- Research and Development: In material research, hardness testing is used to develop and test new materials and processes.

Although a hardness test can be performed as a stand-alone test, it is usually carried out in conjunction with other mechanical tests to obtain an overall assessment of material properties.