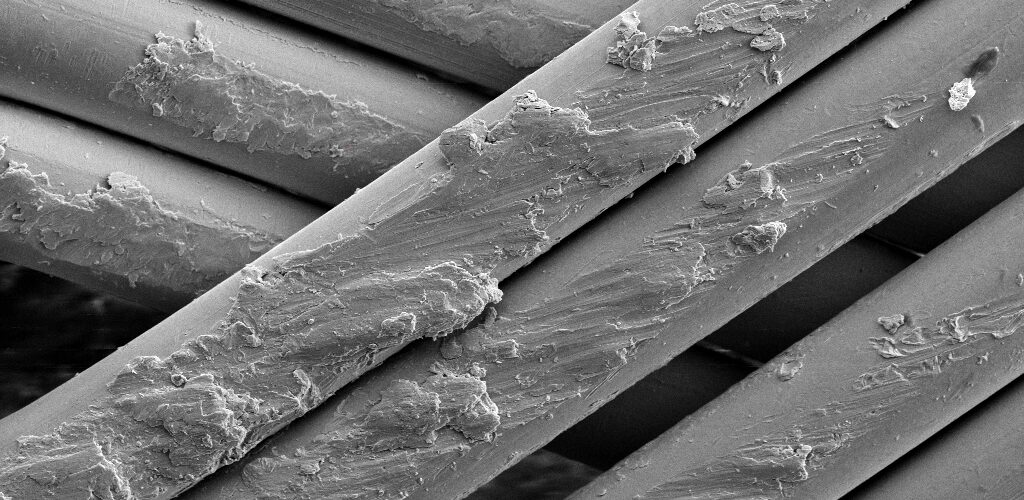

A common failure mode seen during the testing and operation of spacecraft is termed ‘cold-welding’ (‘coldwelding’, ‘contact welding’, ‘adhesion’, ‘sticking’ or ‘stiction’). Coldwelding is a solid-state welding process in which joining takes place without fusion or heating at the interface of the two parts to be welded. This effect mainly concerns metal-to-metal contacts. It was first recognized as a general materials phenomenon in the 1940s: Clean, flat surfaces of metal might strongly adhere if brought into contact in vacuum. Due to missing experimental data, AAC started to setup testing expertise in the 1990ies and continued under ESA-contract to establish a data base.

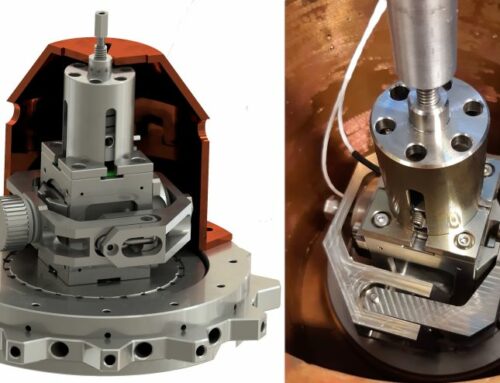

Typical mechanism prone to cold-welding

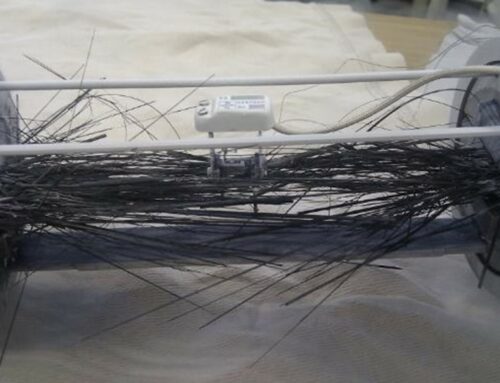

Cold-welding is a significant issue that spacecraft engineers need to consider: In 1991 at the Galileo spacecraft the high-gain antenna failed due to cold-welding issues in the hold-down points of the ribs. In general, metal – metal contacts on a spacecraft are at high risk of cold-welding. These are namely: HDRM (Hold Down and Release Mechanism), stranded wires, mechanical end stops, gear toothing, bearings and many more.

Two situations are considered to be the main points of risk

Cold weld while regular space operation might occur between two metal-metal contacts due to vibration of e.g. motors. AAC is testing those environmental boundary conditions according to STM-279.

Cold-welding in launch situation might be found in any space mechanism with metal-metal contact. While launch and terrestrial transportation all mechanism are exposed to a high level of vibration. Thereby, coatings and surface treatments could be damaged already in air. This can lead to a reduced lifetime for the regular space operation – as experienced at the Galileo spacecraft.

Common false assumptions

At this point I would like to clear up some common, false assumptions and often overlooked problems:

– Cold-weld does not only happen between the same metals, but also between different metals. To give an example for combinations exposed to fretting: SS440C against Ti6Al4V shows adhesion forces up to 10N. Ti6Al4V against itself has around 6N. SS440C against itself has up to 3N adhesion force.

– A commonly overlooked problem is the damage of protective coatings while on-ground testing and handling. All used protective coatings need to withstand not only the harsh environment of launch and space. You also need to consider the preliminary process of storage, handling and testing on ground. We are often confronted with finding solutions in the last minute, because the on-ground burden was underestimated or coldwelding was not considered at all. Please note, that during shaker tests (running in air) coldwelding will not occur. The risk is usually assessed via integrity of the contacting surfaces by post-inspection.

– It is experienced at AAC that potential coldwelding issues are often considered in a late phase while building space mechanism when running first tests in vacuum. But it is much less effort to consider / analyze potential coldwelding issues in an early design phase.

Solutions and way forward

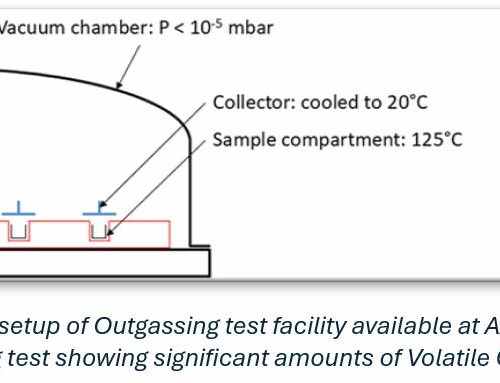

AAC runs different test facilities to test combinations of materials, coatings and lubricants on their tendency to cold welding. Those tests are not cost intense and include typically consultancy – you do not need to be a cold welding professional – this is our job. Use the opportunity and contact us in an early design phase to avoid cold welding issues.

ESA is supporting European space industry with a cold-welding data base, which is run by AAC. Register for free and get access to the cold welding data of the main common used material combinations. – In case your preferred material combination is not available in the database, contact us for further information.

Tribological testing in space environment offered by AAC

Interested in more information or measurement of cold welding? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Space Engineering & Technology