Contamination control is a critical aspect of risk mitigation for contamination sensitive surfaces in satellites. Molecular organic contaminants (MOCs) that are deposited on surfaces like lenses may decrease the performances of instruments. Common monitoring methods that are used in space business include:

TQCM monitoring (Thermally stabilised Quartz Crystal Microbalance), RGA (Residual Gas Analysis), witness foils to collect contaminants for ex-situ analysis, infrared reflection-absorption spectroscopy (IRRAS) or X-ray Photo Spectroscopy (XPS).

The issue is …

… that none of the currently used technique provides a real-time, in-situ quantitative and qualitative analysis of surface contamination during thermal vacuum tests. E.g. residual gas analysis provides in-situ outgassing data but do not provide information about possible condensation on sensitive surfaces. Witness foils – on the other hand – provide data of possible contamination layers on sensitive surfaces. But the transfer of the witness foils from the thermal vacuum chamber to the facility for analysis is done through ambient atmosphere which changes the contamination layer and will differ from the contaminants collected while testing / bakeout.

The solution is …

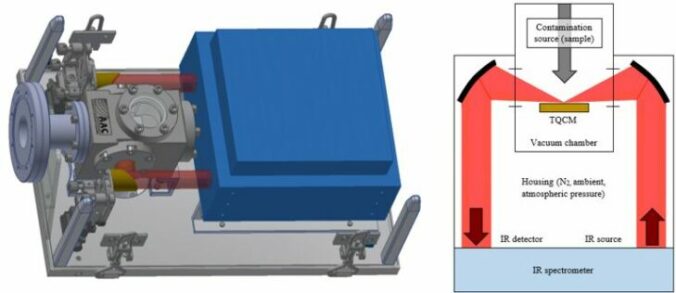

… a combination of quantitative in-situ mass gain analysis (via TQCM) and a qualitative in-situ analysis by their chemical nature on the surface (via IRRAS): The ConMon (CONtamination MONitoring) Sensor is a mobile device that can be attached to thermal vacuum chambers for in-situ contamination monitoring. The TQCM measures the mass gained on a cooled gold surface and the infrared spectroscopy provides information about the type of chemical compound trapped on the quartz. With those two sets of data the bakeout can be evaluated more efficiently, contamination sources can be identified more precisely and bakeout procedures may be adapted in-time instead of running several loops.

The ConMon Sensor from AAC for instance may be used as additional instrument while bakeouts. We have been using the sensor for several thermal vacuum tests in the past years and found it to be a powerful tool for the measurement of contamination due to redeposition of an outgassing sample.

Interested in more information or measurement of contamination? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Space Engineering & Technology