Testing of ball bearings requires to pre-load them axially and/or radially. This needs manual operation by a technician. If bearings shall be characterized for different pre-loads, every change in the pre-load requires to open the vacuum chamber. This means a TVAC test can be run only at one fixed pre-load. On the other hand, a typical thermal vacuum life test starts at room temperature and continues to minimum one cold and one hot temperature level, this means at least 3 days. A change of the pre-load needs return to room temperature and open the chamber. Testing at two pre-load levels lasts then 6 days, testing at three pre-load levels lasts then 9 days and so on.

New Dynax-Test setup

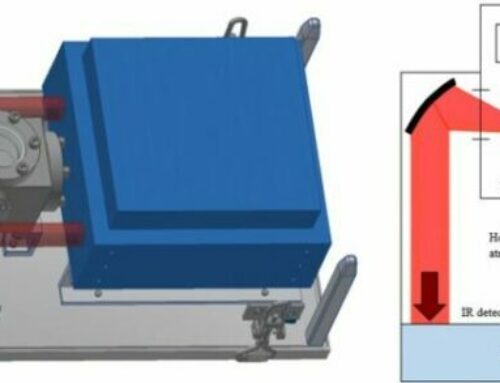

Our new “Dynax”-setup enables to dynamically change the axial pre-load in-situ, i.e. the pre-load can be adopted anytime during a thermal vacuum test. This reduces significantly the testing time. For the example of two pre-load levels, only 3 days are necessary as only one thermal cycle is necessary: after reaching a certain temperature level, the bearings can be characterized on alle necessary pre-loads. This setup is therefore strongly reducing testing times, when a bearing shall be characterized for its torque at different pre-loads.

New Dynax-Test setup with option BiAx

The new setup also enables to pre-load the bearings by a combination of axial and radial pre-load.

Ongoing research

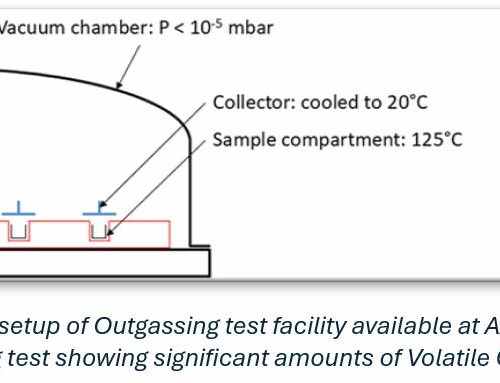

This new setup was recently used to investigate the torque of solid lubricated precision bearings intended for use in a large deployable antenna (LDR). During deployment the pre-load is starting at very low level, but with ongoing deployment the pre-load increases strongly. This situation can experimentally be simulated by our new setup. Moreover, it also enables run these tests in vacuum from -160°C up to +160°C.

Interested in more information or Research and Development of Space Tribology? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Space Engineering & Technology